Strategic Material Testing Lab Services: A Cornerstone of Project Success

Wiki Article

Developments in Product Testing for Enhanced Quality Guarantee

From non-destructive testing techniques to automated systems, the area of material screening has actually seen amazing advancements. In this conversation, we will check out some of the latest patterns in material screening, consisting of the usage of sophisticated sensing unit technologies, the assimilation of data analytics, and the role of man-made intelligence. Let's dive right into the globe of innovations in material testing and uncover just how these developments are forming the future of top quality guarantee.Non-Destructive Checking Methods

Non-Destructive Testing Methods play a crucial role in ensuring the stability and high quality of materials without compromising their structural honesty. These approaches are utilized in various sectors, consisting of aerospace, manufacturing, and building and construction, to identify and identify problems or abnormalities in products or structures. By using non-destructive screening technicians, techniques and engineers can evaluate the buildings, features, and efficiency of products without causing any kind of damages.One frequently made use of non-destructive screening technique is ultrasonic screening (UT) UT involves the usage of high-frequency sound waves to discover flaws such as fractures, spaces, and incorporations in materials.

Non-destructive testing approaches supply beneficial details concerning the quality and integrity of materials, guaranteeing that they meet the required requirements and specifications. By executing these techniques, markets can enhance their quality control processes, reduce the danger of failing or mishaps, and ultimately supply much safer and much more reputable products to customers.

Automated Screening Equipments

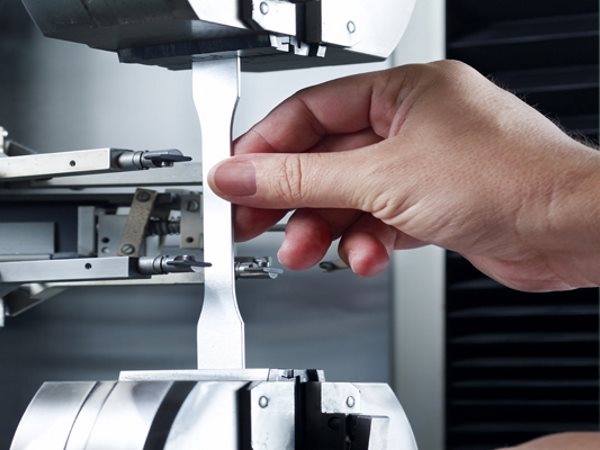

Automated screening systems have revolutionized the field of material testing, offering reliable and precise methods for evaluating the high quality and honesty of products. These systems utilize sophisticated technologies and algorithms to automate the testing process, minimizing human mistake and raising efficiency.One key advantage of automated screening systems is their capability to carry out examinations at a much faster price than manual screening techniques. With making use of robotics and sophisticated software program, these systems can perform multiple examinations concurrently, considerably lowering the time required for screening large sets of materials.

In addition, automated screening systems offer a higher degree of precision and accuracy contrasted to hands-on testing. They can perform tests with consistent criteria, guaranteeing that the outcomes obtained are reproducible and trustworthy. By eliminating human subjectivity and variability, these systems supply a more objective assessment of worldly top quality.

Additionally, these systems are outfitted with sophisticated sensors and detectors that can detect even the tiniest issues or discrepancies in product residential properties. This enables early detection of potential concerns, permitting suppliers to take corrective activities prior to the materials are used in vital applications.

Along with their efficiency and precision, automated testing systems additionally boost safety and security in material screening. By minimizing human involvement in possibly hazardous testing treatments, these systems decrease the risk of injuries and accidents, ensuring a more secure working environment.

Advanced Sensor Technologies

With the assimilation of advanced sensing unit modern technologies, material screening systems have actually accomplished also better degrees of precision and efficiency (material testing lab). Advanced sensor modern technologies play a critical function in enhancing the quality control procedure by supplying real-time and precise information throughout material testing. These sensing units can identifying and gauging numerous physical properties such as temperature, stress, vibration, and stress, permitting a comprehensive analysis of the product's behavior under various conditionsOne of the crucial improvements in sensing unit technologies is the development of wireless sensing units. These sensors eliminate the demand for difficult wiring and allow smooth information transfer, enhancing the general flexibility and flexibility of the screening process. Furthermore, cordless sensing units can be conveniently incorporated right into existing product screening systems, making them a cost-efficient remedy for Continued improving and upgrading testing abilities.

Expert System in Material Testing

Expert system has transformed the field of product screening, bringing unmatched degrees of precision, performance, and predictive capabilities to the quality control process. With the capability to evaluate large quantities of information and identify patterns that may go undetected by human operators, AI formulas have substantially enhanced the reliability of material screening procedures.One of the crucial advantages of making use of AI in product testing is its capability to anticipate material behavior under different problems. By educating AI versions on historic data, researchers can establish anticipating models that can estimate the efficiency of products in real-world scenarios. This enables producers to enhance material choice and design, decreasing the demand for lengthy and expensive trial-and-error processes.

Additionally, AI can improve the product and automate testing process, enhancing effectiveness and minimizing human mistake (material testing lab). AI-powered systems can autonomously perform testing procedures, gather and assess data, and create detailed records. This not just conserves learn this here now time yet likewise makes sure dependable and regular outcomes

Moreover, AI can detect and evaluate material defects or abnormalities with high precision. By contrasting examination results to predefined criteria, AI algorithms can swiftly identify inconsistencies and alert drivers to potential issues. This early discovery of problems aids stop defective products from going into the production procedure, eventually improving product quality and consumer complete satisfaction.

Integration of Information Analytics

Data analytics plays a crucial duty in the integration of product screening processes, enabling makers to remove important insights and make notified decisions. By utilizing innovative analytic methods, makers can evaluate big volumes of information collected throughout material testing to recognize patterns, trends, and abnormalities that might impact the quality and efficiency of their items.Combination of data analytics in material screening allows producers to monitor and assess different parameters and variables throughout the screening process. This includes factors such as temperature level, stress, strain, and other environmental problems that can affect the habits and attributes of products. By evaluating this data, suppliers can acquire a much deeper understanding of how different variables influence the efficiency and communicate of their products.

Additionally, data analytics helps in recognizing potential defects or weaknesses in materials, allowing makers to take positive steps to attend to these problems prior to they result in item failures or safety and security threats. This proactive strategy can dramatically improve the overall quality control process and improve consumer fulfillment.

In enhancement to identifying flaws, information analytics can additionally maximize material screening procedures by recognizing locations of renovation and suggesting modifications in the testing protocols. By evaluating historical data, manufacturers can identify patterns and trends that can assist them improve their testing processes, minimize expenses, and enhance efficiency.

Verdict

Non-destructive testing techniques, automated screening systems, progressed sensor innovations, and the assimilation of information analytics have all played a significant role in improving the accuracy and effectiveness of material testing procedures. Additionally, the application of man-made intelligence in product screening has actually additionally contributed to the development of even more reliable and specific screening methods.From non-destructive testing methods to automated systems, the field of product testing has actually seen impressive advancements. Wireless sensing units can be easily incorporated right into existing product testing systems, making them an economical service for enhancing and updating screening capabilities.

Integration of information analytics in more tips here product screening allows makers to check and examine various criteria and variables throughout the screening process. Non-destructive screening methods, automated screening systems, progressed sensing unit modern technologies, and the assimilation of data analytics have all played a substantial duty in boosting the accuracy and efficiency of material testing procedures. In addition, the application of fabricated knowledge in material screening has further contributed to the growth of even more accurate and reliable testing strategies.

Report this wiki page